Post Date:17,Jul,2023

The most common post construction problems of internal wall putty powder are peeling and whitening. To understand the reasons for the peeling of internal wall putty powder, it is necessary to first understand the basic raw material composition and curing principle of internal wall putty powder. Then, based on the dryness, water absorption, temperature, and weather dryness of the wall during putty construction, identify the main reasons for the peeling of internal wall putty powder and use corresponding methods to solve the problem of putty powder peeling

一、 Basic raw material composition of interior wall putty powder:

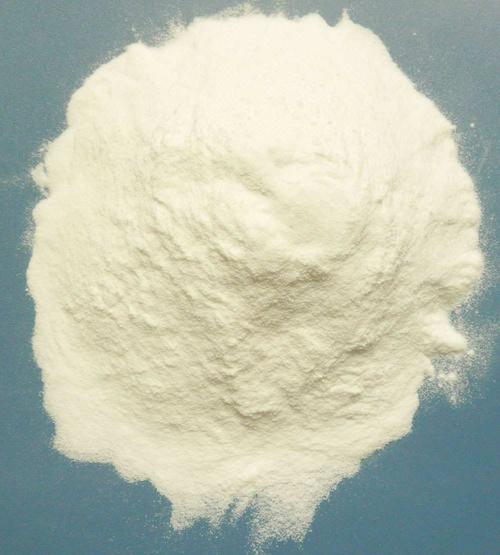

The most basic components of interior wall putty powder include: inorganic bonding material (gray calcium), fillers (heavy calcium powder, talcum powder, etc.), and polymer additives (HPMC, polyvinyl alcohol, rubber powder, etc.). Among them, interior wall putty powder generally does not add white cement or only adds a little white cement. Redispersible latex powder has little effect at low dosage, so it is mainly not used in interior wall putty powder due to cost issues or is rarely used.

So due to the issue with the formula of interior wall putty powder itself:

1. Inorganic bonding materials, such as low addition of gray calcium and substandard quality of gray calcium;

2. The addition of bonding components in polymer additives that are too low or do not meet the quality standards may cause the internal wall putty powder to fall off.

二、Curing mechanism of interior wall putty powder:

The curing of interior wall putty powder mainly relies on the synergistic effect of lime calcium powder, HPMC and other polymer additives under wetting conditions to solidify, form a film, and stabilize the curing process.

The hardening principle of gray calcium powder:

Drying and hardening: During the scraping process, a large amount of water evaporates from the gray calcium powder, forming a large network of identical pores in the slurry. The free water remaining in the pores, due to the surface tension of the water, generates capillary pressure, making the gray calcium powder particles more compact, thus obtaining strength. When the slurry is further dried, this effect is also strengthened. Crystallization hardening: Highly dispersed colloidal particles in the slurry are separated by the diffusion layer between the particles. As the water content gradually decreases, the diffusion layer gradually thins, and thus the colloidal particles adhere to each other under the action of molecular forces, forming a spatial network of condensed structures, thereby obtaining strength. Carbon hardening: The slurry absorbs CO2 gas from the air, forming calcium carbonate that is actually insoluble in water. This process is called carbonation of slurry. The co reactions are as follows:

Ca(OH)2+CO2+H2O→CaCO3+(n+1)H2O

The generated calcium carbonate crystals coexist with each other or with calcium hydroxide particles, forming a tightly intertwined crystal network, thereby improving the strength of the slurry. In addition, due to the slightly increased solid volume of calcium carbonate compared to calcium hydroxide, the hardened gray calcium powder slurry tends to be more solid. 3、 After putty powder is applied to the wall, the water in the putty is mainly lost through three ways:

The water evaporation on the surface of the putty when the gray calcium and white cement react in the absorbent putty powder of the basic wall surface. 3. The influence of construction factors on the powder shedding of the putty powder:

The reasons for powder loss caused by construction include: poor maintenance conditions causing the putty to dry too quickly and not having enough strength; The basic wall surface is too dry, causing the putty to quickly lose water; Excessive thickness of putty in a single batch.

Post time: Jul-17-2023