Ranar Wasanni:17,Jul,2023

Mafi yawan al'adun ginin gidan waya na bango na ciki Putty foda yana da lesing da farin ciki. Don fahimtar dalilan peeling na bango na ciki Putty foda, ya zama dole don fara fahimtar ainihin albarkatun ƙasa da kuma magance ka'idar bangon bango na ciki foda. Bayan haka, dangane da bushewa, shayarwa, da bushewar bango a lokacin da Peeling na bango Putty Forming na ciki da amfani da hanyoyin da suka dace don magance matsalar Pavering everder evering

一, ainihin albarkatun ƙasa da kayan haɗin ciki na ciki bango na ciki:

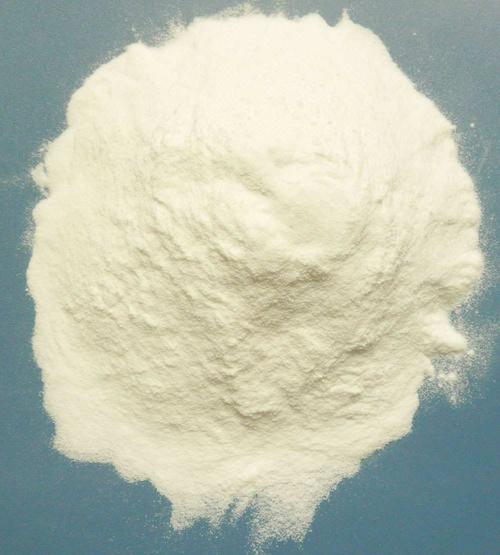

Mafi yawan abubuwan da aka gyara na ciki bango na ciki sun hada da: kayan haɗin kai (alli mai launin toka), masu yawa, masu yawa, da ƙari, foda mai yawa, da sauransu), da sauransu, foda, da sauransu, da sauransu). Daga gare su, bangon bango na ciki na ciki ba ya ƙara farin ciminti ko kuma ƙara ɗan farin ciminti. Redex foda foda yana da ƙarancin tasiri a ƙananan sashi, don haka galibi ba a amfani da shi a cikin foda na ciki na ciki saboda farashin farashi ko ba a amfani da shi.

Don haka saboda batun tare da dabara na cikin kamannin bango na ciki foda kanta:

1. Abubuwan Bondganic na Bada, kamar Oargardaya daga Bugu da kari na Grey Calcium da ingancin ingancin ƙididdigar launin toka;

2. Bugu da kari abubuwan haɗin gwiwar a cikin abubuwan polymer wanda sun yi ƙasa ko kaɗan ko ba su cika ƙa'idodin ƙimar na iya haifar da foda na ciki ba.

, Magance tsarin kayan jikin bango na ciki:

A lokacin da ke cikin bangon bango na ciki galibi ya dogara da tasirin synergistic na lemun tsami calcium na a karkashin yanayin rigar don ƙarfafa, samar da fim, da kuma daidaita tsarin aikin.

Ka'idar Hardening na launin toka Calcium Foda:

Bushewa da Hardening: A lokacin aiwatar da tsari, babban adadin ruwa ya bushe daga launin toka foda, samar da babban hanyar sadarwa iri daya a cikin slurry. Ruwan da ya rage a cikin pores, saboda tashin hankali na ruwa, saboda matsi na ruwa na barbashi, yana yin ƙarfi mai launin toka, don haka samun ƙarfi. Lokacin da aka inganta slurry ya bushe, an kuma karfafa wannan sakamako. Crystallization Hardening: Crysteled crupsed colloidal barbashi a cikin slurry rago da rabuwa da yaduwa a tsakanin barbashi. Kamar yadda cikin abun ciki na ruwa a hankali yake raguwa, wanda a hankali ya yadu a hankali, kuma ta haka ne sannu-sannu sannu-sannu thins, kuma ta haka ne sannu a hankali na kwastomomi a karkashin aikin rundunonin kwayar halitta, ta yadda samun karfi. Carbon Hardening: Slurry yana shan gas mai gas na CO2 daga iska, samar da Clium Carbonate wanda yake zahiri shiga cikin ruwa. Ana kiran wannan tsari carbonation na slurry. A co amsa kamar haka:

CA (OH) 2 + CO2 + H2O → Caco3 + (n + 1) h2o

A gurbataccen calbonate lu'ulu'u masu cuta mai hankali tare da juna ko tare da allon hydroxide barbashi, don ƙirƙirar hanyar sadarwa ta cryalter, ta yadda ke inganta karfin slurry. Bugu da kari, saboda dan kadan karuwa da karfi carbonate na alli idan aka kwatanta da alli hydroxide, sl taurarin alli mai launin toka slurry yana iya zama m. 3, bayan putty foda ana amfani da bango, ruwan a cikin Putty an yi asara sosai ta hanyoyi uku:

A ruwa mai ruwa a saman pavy lokacin da mai launin toka mai launin toka da fari ciminti amsa a cikin putty foda na asali bango. 3. Tasirin dalilai na gine-gine a kan foda na foda na putty foda:

Dalilan asarar foda rasa ta hanyar gini sun hada da: Yanayin kulawa mara kyau na haifar da Putty don bushe da sauri kuma baya samun isasshen ƙarfi; A bangon bango na asali ya bushe sosai, yana haifar da abin da ke faruwa don rasa ruwa da sauri; Yawan kauri na Putty a cikin tsari guda.

Lokaci: Jul-17-2023