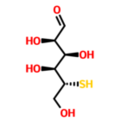

Sodium gluconate is a white granular crystalline solid, which is easily soluble in water. It is the sodium salt of gluconic acid, which is produced by the fermentation of glucose. It is non-corrosive, non-toxic, biodegradable and renewable. It is resistant to oxidation and reduction even at high temperatures. Sodium gluconate forms stable chelate with calcium, iron, copper, aluminum and other heavy metals. Sodium gluconate is a chelating agent superior to EDTA, NTA and phosphonates. Its main characteristic is its excellent chelating power, especially in alkaline and concentrated alkaline solutions.

What does it do?

Food Grade 99% Sodium Gluconate(SG-A) is used as a natural preservative. It prevents the growth of microbes in our products to keep them safe for our consumers. It also works as a chelator (or sequestrant) which helps cleansing products to foam better in hard water.

How is it made?

Food Grade 99% Sodium Gluconate(SG-A) is most often made by the aerobic fermentation of a sugar, which can come from corn or beets, to produce gluconic acid. The fermentation product, gluconic acid, is neutralized to create Food Grade 99% Sodium Gluconate(SG-A).

According to the application, we divide sodium gluconate into industrial use and food grade. Today, we will introduce the role of our industrial grade sodium gluconate in concrete.

What’s the role of our industrial grade sodium gluconate in concrete?

Conrete Retader Sodium Gluconate(SG-B) is used as a cement admixture: adding a certain amount of sodium gluconate to cement can increase the plasticity and strength of the concrete, and has a retarding effect. That is to delay the initial and solidification period of concrete. For example, adding 0.15% sodium gluconate can prolong the initial solidification time of concrete by more than 10 times, which is to extend the plastic time of concrete from a few hours to several days without affecting its fastness Spend.

Conrete Retader Sodium Gluconate(SG-B) as a cement admixture has been widely used in important construction projects abroad, such as a large number of bridge projects in the Middle East. However, the application in this area in our country has not been promoted. It is said that sodium cellulose sulfonate is extracted from papermaking wastewater, and its effect is not comparable to that of sodium gluconate.

Sodium gluconate is used as a cement admixture: adding a certain amount of sodium gluconate to cement can increase the plasticity and strength of the concrete, and has a retarding effect. That is to delay the initial and solidification period of concrete. For example, adding 0.15% sodium gluconate can prolong the initial solidification time of concrete by more than 10 times, that is, extend the plastic time of concrete from a few hours to a few days without affecting its firmness. Spend.

industrial grade sodium gluconate as a cement admixture has been widely used in important construction projects abroad, such as a large number of bridge projects in the Middle East. However, the application in this area in our country has not been promoted. It is said that sodium cellulose sulfonate is extracted from papermaking wastewater, and its effect is not comparable to that of sodium gluconate.

Concrete Retarding agent Sodium Gluconate is used as a retarder. Sodium gluconate can significantly delay the initial and final setting time of concrete. When the dosage is less than 0.15%, the logarithm of the initial solidification time is proportional to the dosage, that is, the dosage is doubled, and the initial solidification time is delayed to ten times, which makes the working time from very long. Extend from a few hours to a few days without compromising strength. This is an important advantage especially in hot weather and when it needs to be placed for a long time.

As a retarder, Concrete Retarding agent Sodium Gluconate can significantly delay the initial and final setting time of concrete. When the dosage is less than 0.15%, the logarithm of the initial solidification time is proportional to the dosage, that is, the dosage is doubled, and the initial solidification time is delayed to ten times, which makes the working time from very long. Extend from a few hours to a few days without compromising strength. This is an important advantage especially in hot weather and when it needs to be placed for a long time.

Post time: Sep-24-2021