Post Date:9,Jan,2023

What are water reducers?

Water reducers (such as Lignosulfonates) are a type of admixture that is added to concrete during the mixing process. Water reducers can reduce the water content by 12-30% without compromising the workability of concrete or the mechanical strength of concrete (which we usually express in terms of compressive strength). There are other terms for Water reducers, which are Superplasticizers, plasticizers or high-range water reducers (HRWR).

Types of water-reducing Admixtures

There are multiple types of water-reducing admixtures. Manufacturing companies give different names and classifications to these admixtures such as water-proofers, densifiers, workability aids, etc.

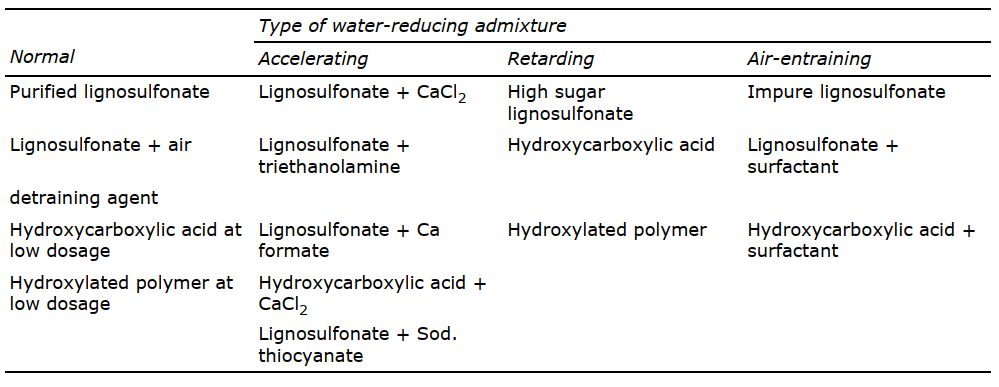

Generally, we can categorize water-reducers into three types according to their chemical composition (as in Table 1):

lignosulfonates, hydroxycarboxylic acid, and hydroxylated polymers.

Where does Lignin come from?

Lignin is a complex material which represent roughly 20% of the composition of wood. During the process for the production of paper-making pulp from wood, a waste liquor is formed as a by-product containing a complex mixture of substances, including decomposition products of lignin and cellulose, sulfonation products of lignin, various carbohydrates (sugars) and free sulfurous acid or sulfates.

Subsequent neutralization, precipitation and fermentation processes produce a range of lignosulfonates of varying purity and composition depending on a number of factors, such as the neutralizing alkali, the pulping process used, the degree of fermentation and even the type and age of the wood used as pulp feedstock.

Lignosulfonates as Water-reducers in Concrete

Lignosulfonate superplasticizer dose is typically 0.25 percent, which can result in water reductions of up to 9 to 12 percent in cement content (0.20-0.30%). As used in the proper dosage, concrete strength improved by 15-20% when compared to the reference concrete. Strength grew by 20 to 30 percent after 3 days, by 15-20 percent after 7 days, and by the same amount after 28 days.

Without altering the water, concrete may flow more freely, making it easier to work with (i.e. increasing workability).

By using one tonne of lignosulfonate superplasticizer powder instead of cement, you may save 30–40 tonnes of cement while maintaining the same concrete slump, intensity, and reference concrete.

In the standard state, concrete mixed with this agent may delay the peak heat of hydration by more than five hours, the final setting time of concrete by more than three hours, and the setting time of concrete more than three hours compared to reference concrete. This is advantageous for summer construction, commodity concrete transport, and mass concrete.

Lignosulfonate superplasticizer with micro-entraining can enhance the concrete’s performance in terms of freeze-thaw impermeability.

Post time: Jan-10-2023