Post Date:27,Jun,2023

1. Water consumption issue

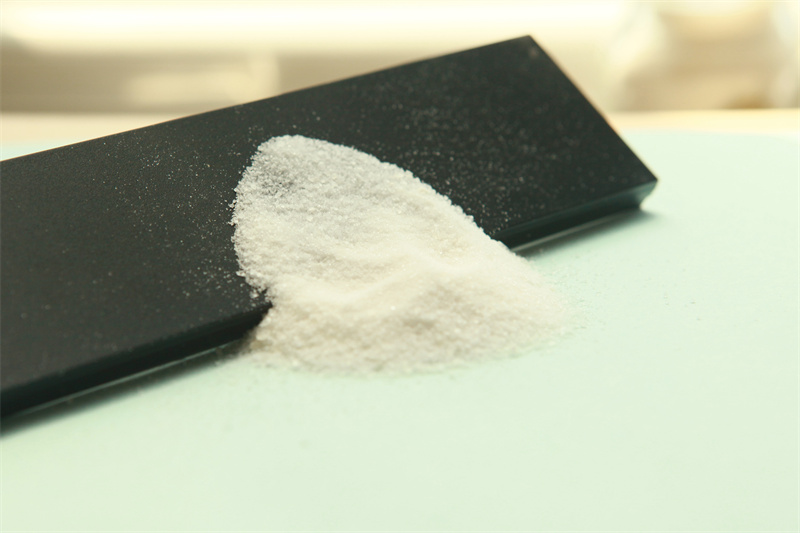

In the process of preparing high-performance concrete, attention should be paid to selecting fine slag and adding a large amount of fly ash. The fineness of the admixture will affect the water reducing agent, and there are problems with the quality of the admixture, which will inevitably affect the performance of the concrete. If the adaptability of slag is good, the proportion of admixture should not be too large, otherwise it is likely to cause bleeding problems. It is necessary to control the proportion of fly ash in concrete to ensure that the water reducing agent plays a better role.

2. Mixing amount issue

Reasonable allocation of fly ash and slag can improve the performance of concrete, reduce the use of cement in engineering construction, and reduce material costs. The fineness and quality of the admixture will affect the effectiveness of the water reducing agent. Improving the performance of concrete requires certain requirements for the fineness and quality of the admixture. In the process of configuring high-performance concrete, the application of slag powder in the admixture can improve its performance. The amount of admixture should be reasonably configured according to the actual engineering situation, and the dosage should be controlled.

3. Water reducing agent dosage issue

The application of water reducing agents in commercial concrete requires a scientific understanding of the amount of water reducing agents used and reasonable control of their proportions. Select different types of water reducing agents based on the type of cement in the concrete. In construction projects, the dosage of water reducing agents needs to be determined after multiple tests to obtain the best state.

4.Aggregate issues

The aggregates used in concrete need to be evaluated from multiple perspectives, with the main evaluation indicators including shape, particle grading, surface structure, mud content, concrete mud content, and harmful substances contained. These indicators will have a certain impact on the quality of aggregates, and special attention should be paid to the mud content. The content of mud blocks in concrete cannot exceed 3%, otherwise even if water reducing agents are added, the quality of concrete cannot meet the standard. For example, a certain construction project uses C30 cast-in-place pile concrete. During the trial mixing process of the concrete, when the water reducing agent ratio is 1%, it can meet the engineering requirements, including fluidity, slump expansion, etc. However, adding water reducing agents according to experimental data during the construction process cannot meet the engineering requirements or meet the specified standards. After expert inspection and analysis, it was concluded that the main reason for this phenomenon is that the mud content in the fine aggregate exceeds 6%, which affects the water reducing effect. In addition, different shapes of coarse aggregate particles can also affect the water reducing effect of the water reducing agent. The fluidity of concrete will decrease with the increase of materials and coarse aggregates. After scientific analysis, it is not enough to rely solely on water reducing agents to improve the practical effect of concrete and enhance its strength. It is necessary to optimize the mix of concrete in order to achieve good results.

Post time: Jun-27-2023