Post Date:6,May,2025

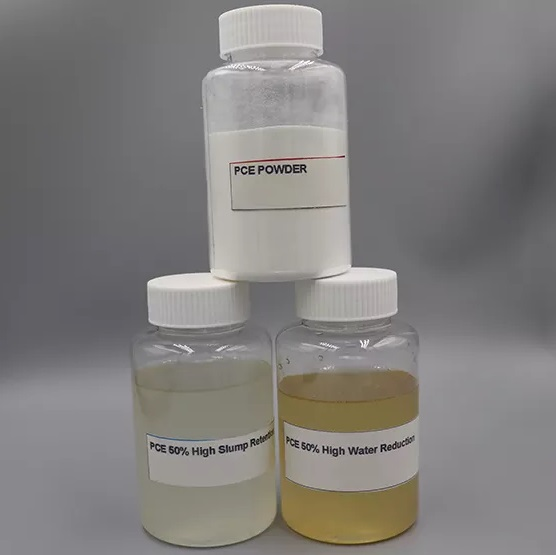

(1) Excessive use of Polycarboxylate Superplasticizer

Polycarboxylate Superplasticizer has the characteristics of high water reduction rate and low dosage (about 0.20% solid), which can significantly improve the slump of concrete without changing the water consumption of concrete. Like other types of water reducers, the water reduction rate of Polycarboxylate Superplasticizer has a certain degree of positive correlation with the dosage. Generally speaking, as the dosage increases, the water reduction rate also increases. When designing the concrete mix ratio, attention should be paid to selecting the amount of admixture that matches the water consumption. For example, when the water consumption of C30 concrete is 170kg/m', the water reduction rate of the water reducer should be about 20%. When the water consumption of C50 concrete is 160kg/m, the water reduction rate should be about 25%~30%. When the water-reducing agent dosage does not match the water-reducing rate of the concrete mix design water consumption, such as excessive dosage and excessive water-reducing rate, its dispersing ability will be significantly enhanced, which will significantly reduce the cohesiveness of the concrete, causing more free water to be released, resulting in the occurrence of water bleeding in the concrete mixture. In particular, when using a slow-release slump-retaining Polycarboxylate Superplasticizer, excessive dosage can easily cause serious water bleeding in the concrete, resulting in segregation. Therefore, when using a Polycarboxylate Superplasticizer, a time-dependent test should be conducted first to observe the changes in the state of the concrete to determine its dosage.

(2) Polycarboxylate Superplasticizer is more sensitive to ambient temperature and has slow-release properties

Compared with other water-reducing agents, the water-reducing performance and slump-retaining performance of polycarboxylic acid water-reducing agents are more affected by temperature. In practice, it is found that the water-reducing rate in winter is slightly lower than that in summer at the same dosage, but the slump-retaining effect is better than that in summer. When the temperature is high in summer, a polycarboxylic acid water-reducing agent with good slump-retaining performance may experience a "reverse" slump when the temperature suddenly drops. Practice has found that when the temperature changes suddenly, the water reducer content increases or decreases by 0.1% to 0.2% (the base content is 2%) for every 10°C change in temperature. Therefore, when using polyacid water reducer when the temperature drops suddenly, attention should be paid to observing the changes in the state of the concrete, and the original polycarboxylic acid water reducer should be tested to determine the appropriate content according to the temperature change. At the same time, the mixing time should be appropriately extended during concrete production, especially for concrete with a strength grade higher than C50, which has a large water reducer content. It is more important to extend the mixing time so that the polycarboxylic acid water reducer is fully dispersed and released, so as to avoid the slow release in the later stage, which will cause the concrete to retain water.

Post time: May-06-2025